The JUKI LBH-1790AN Series is a high-speed, computer-controlled buttonholing system built for industrial garment manufacturing. It is designed to provide consistent, high-quality buttonholes efficiently, catering to a wide range of fabric types and garment applications.

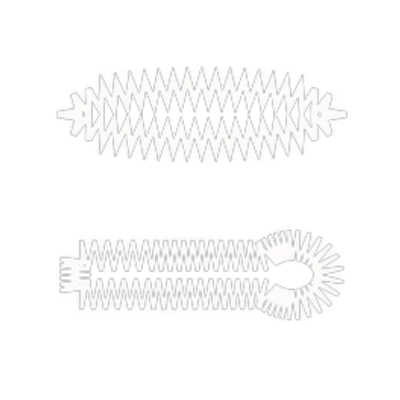

LBH-1790AN (Standard Model)

Suitable for general-purpose buttonholing on a variety of garments, including shirts and blouses.

LBH-1790ANB (Shorter-Thread Remaining Functions)

Reduces thread waste and ensures clean finishes, making it ideal for high-end garments.

LBH-1795AN (120mm Presser Type)

Designed for creating larger buttonholes up to 120mm, commonly used in coats and jackets.

LBH-1796AN (220mm Presser Type)

Handles extra-large buttonholes up to 220mm, suitable for heavy-duty garments like overcoats and industrial wear.

This series offers reliable solutions for manufacturers looking to produce accurate and durable buttonholes efficiently. Magnum Resources provides these machines with full support, including installation, training, and after-sales service.

Ensures consistent and accurate buttonholing, reducing material wastage and operator error.

Minimizes thread waste and enhances the finished garment’s appearance by reducing loose ends.

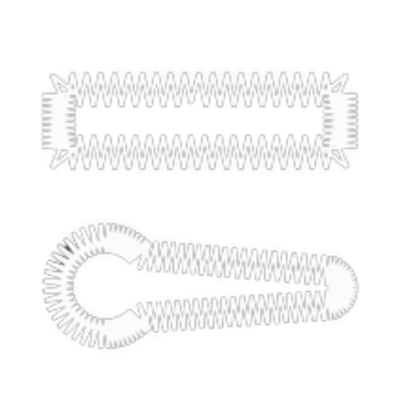

Accommodates buttonholes of various lengths, ranging from standard sizes to extra-large options (up to 220mm)

Includes programmable settings for different buttonhole designs, catering to diverse garment requirements.

User-Friendly Control Panel with an intuitive digital interface for quick setup, pattern selection, and real-time adjustments.

Reduces power consumption while ensuring consistent performance, aligning with sustainable manufacturing goals.

Automatically trims threads after stitching, ensuring clean finishes and reduced manual intervention.

Heavy-Duty Needle Penetration ensures smooth stitching on a wide range of fabrics from lightweight materials to thicker and heavier fabrics.

Perfect for precise and consistent buttonholes on formal shirts, blouses, and casual wear.

Ideal for creating larger buttonholes on coats, jackets, and outerwear.

Ensures shorter-thread remaining for neat, professional-grade garment finishes.

Yes, Magnum Resources offers installation support, operator training, and ensures the availability of genuine spare parts whenever required, along with after-sales service.

The LBH-1790AN Series can produce a wide range of buttonholes, including standard, large (up to 120mm), and extra-large (up to 220mm) to meet diverse garment manufacturing needs.

Yes, Magnum Resources provides access to genuine JUKI spare parts and comprehensive maintenance services to keep your machine running efficiently.

If you want to know more information or have any questions,

you can contact us. We will be

happy to help!