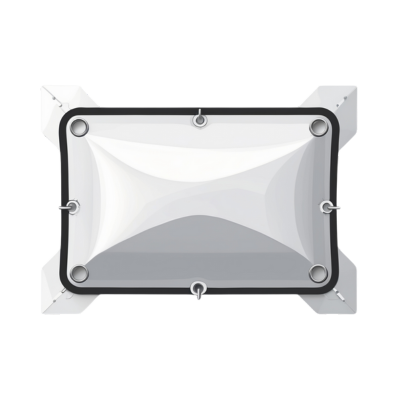

The RFlex Welding Machine is engineered for seamless, high-quality welding of a wide range of materials, including heavy-duty fabrics, PVC, and polyethylene. With its combination of hot air and hot wedge technologies, it offers flexibility and precision across various applications. The RFlex provides high efficiency, rapid operation, and durability, ensuring maximum uptime in production environments.

Perfect for fabricators, manufacturers, and industrial applications, the RFlex enables optimal results with minimal waste, contributing to reduced costs and improved production workflows.

Key Features:

Universal usage for PVC, PU, TPU, reinforced technical textiles

Foldable large worktable with deep trough creating ample space behind the electrode for easy material handling

New generation stable and efficient RF power generator

Easily change dies with QuickGRIP release system of the electrodes

Easier material placement and better visualization of weld with built in LED illumination.

Manual, semi-automatic and automatic operation

SafeDOWN anti-crush electrode safety motion system

Fully automated weld cycles with 100 weld cycle recipe memory

Enables custom protective covers for machinery, equipment, and outdoor furniture with weatherproof seams.

Ideal for producing robust tents and canopies that withstand harsh conditions, perfect for outdoor events and disaster relief.

Reinforce tarps and covers with durable eyelets.

The RFlex offers precise welding control, ensuring consistent, durable seams for automotive covers, seat cushions, and other upholstery applications.

Yes, the RFlex is built to handle large-scale industrial projects, ensuring high-speed, reliable welds for heavy-duty fabrics.

The RFlex can achieve a maximum welding speed of up to 30 meters per minute, offering efficient production for high-volume manufacturing.

If you want to know more information or have any questions,

you can contact us. We will be

happy to help!